-

Certified Company

EN 1090-2:2018, EXC3

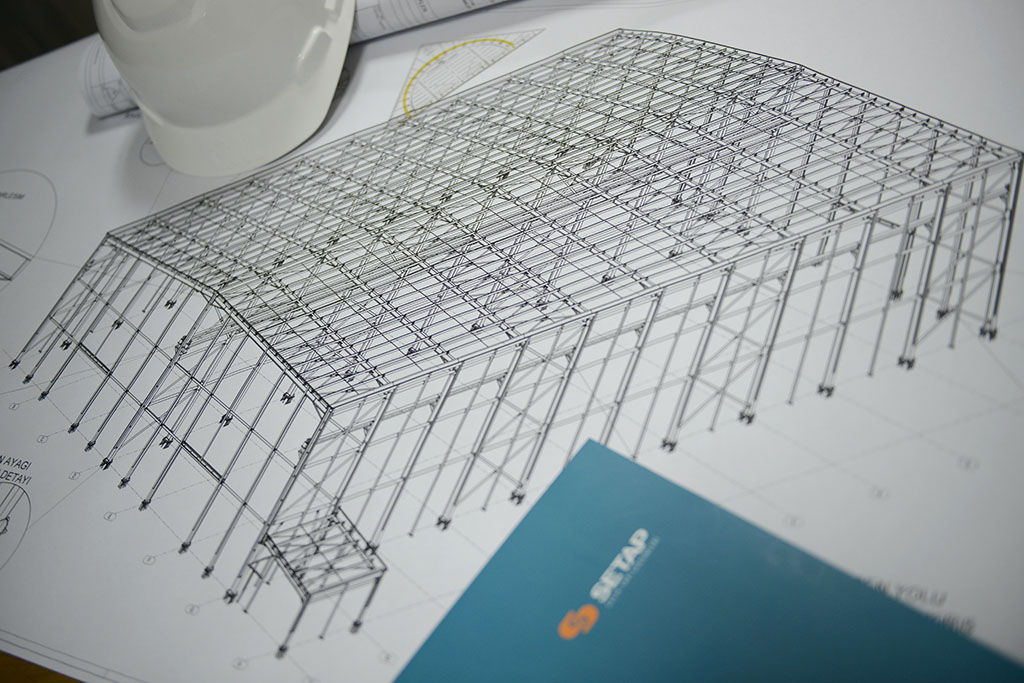

SETAP designs its projects in a 3D environment in coordination with customers, customer representatives and other partners. The design results are presented to the customer along with the material list, work schedules, work flow diagrams and methodology reports.

The experienced project team, who knows the manufacturing and application very well, is supported by an independent controller and consultant team consisting of academicians.

The engineering team, who graduated from internationally reputable universities and made static designs using international standards, especially EUROCODE, supports the architectural team that designs the wishes of its customers.

SETAP superpose all project disciplines (architectural, static, mechanical and electrical) with each other and thus prevents possible incompatibilities in the construction site.

The shop drawings drawn in the project office are transferred online by the manufacturing engineers to the production line and the production processes are followed online by the project department along the production lines.

Contact Us: setap@setapyapi.com

Copyrights © 2020 All Rights Reserved. Powered by SETAP Yapı.