-

Certified Company

EN 1090-2:2018, EXC3

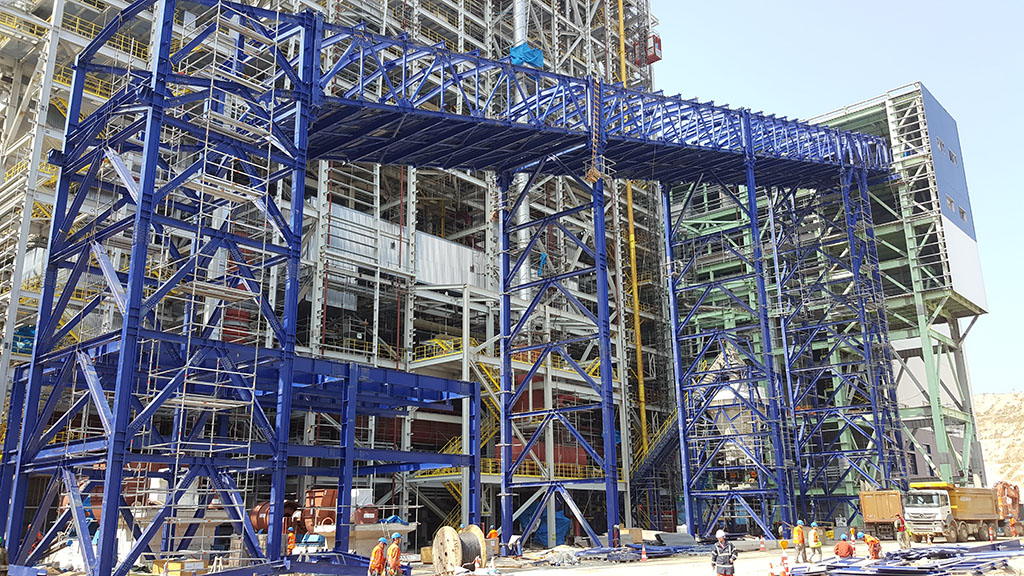

Structural steel system; Especially used for structures that require large spans, lengths, or heights. These are usually production systems in the iron and steel, chemical, automotive and food industries.

In addition to large-scale production facilities, large-scale multi-store buildings, skyscrapers, shopping malls, sports halls, stadiums, trade centers, fair center, airports and bridges are among the structures where structural steel system is preferred.

In SETAP, all project work is done in three dimensions by using software integrated with production lines. Thus, possible incompatibilities in the construction site are prevented.

SETAP completes the assembly of construction parts with bolt connections at the construction site. Most of the construction production is completed in the production facility. Thus, assembly errors in the construction site are minimized, saving time and money.

The characteristics that play an important role in the preference of buildings with structural steel construction are as follows;

• Thanks to its flexibility, it responds very well to earthquake,

• It is preferred in specific designed structures due to its flexible design possibilities,

• It is constructed in a much shorter time compared to its alternatives, since it is pre-manufactured and the assembly made only with bolt connections is completed very quickly,

• The entire construction, which can be disassembled and reassembled, can be reused without any loss,

• The fact that steel, which is the raw material used, is a recyclable material, provides an environmentally friendly structure,

• Thanks to the preproduction, the entire construction process is under control and does not require any operation other than bolt connections at the assembly site. In this way, the surprise negativities that may be experienced later on the construction site are minimal.

Contact Us: setap@setapyapi.com

Copyrights © 2020 All Rights Reserved. Powered by SETAP Yapı.